Our mission is to bring latest breakthroughs in Artificial Intelligence and Machine Learning to small and medium size manufacturers to improve their ROI. We achieve this by creating a highly adaptable data driven real-time software solution that minimizes configuration and lowers the cost of implementation. Try our interactive demos to see for yourself and compare simplicity of our solution with competition.

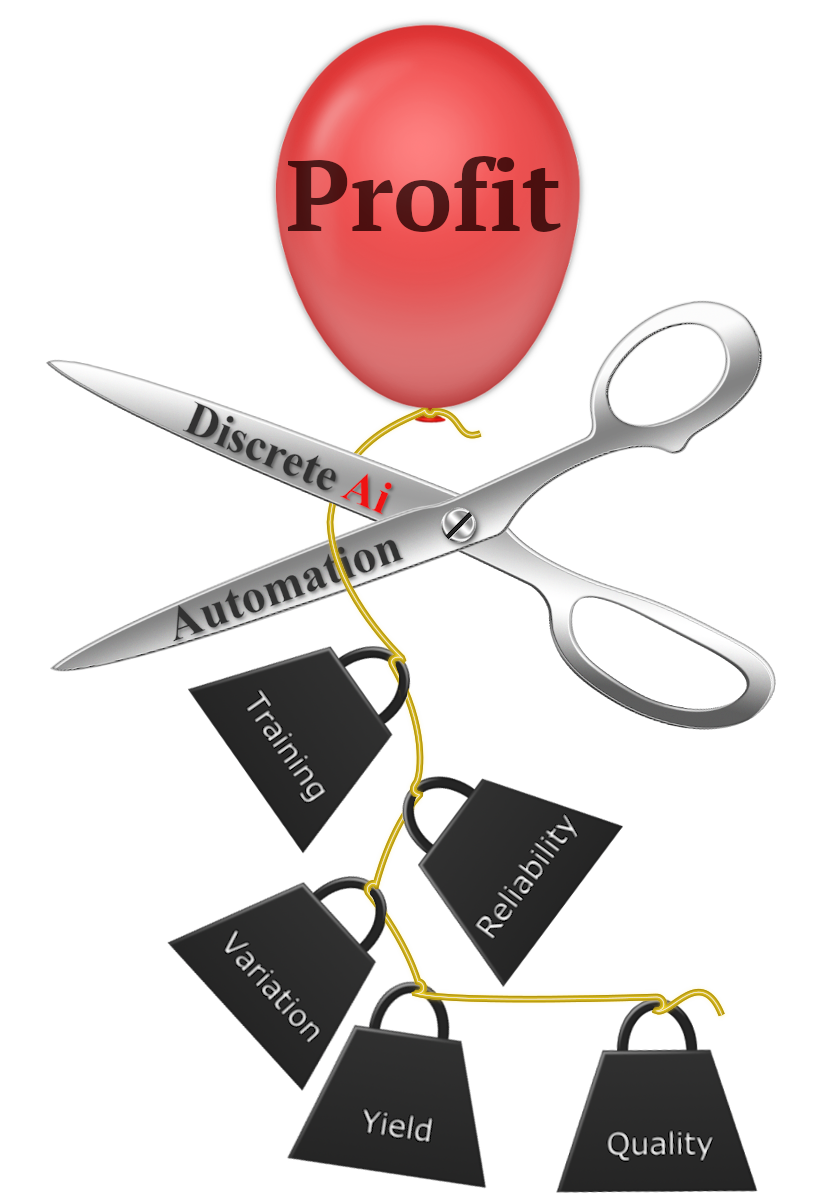

Production efficiency and product yield are the most important profit margin parameters for manufacturers. These parameters are impacted by a combination of factors including input material, product flow, equipment reliability, system variance and operator trainings etc. We have developed agile software to improve manufacturing efficiency while providing analytical information to make strategic decisions. Our software is based on proprietary discrete event driven architecture that combines proprietary statistical model with predictive machine learning algorithm and data visualization techniques.

Our data driven technology requires minimal configuration to improve factory performance. Our customers will see an improvement in their manufacturing assets performance as we guarantee a 10% ROI . Our real-time yield analysis software is totally free for a limited # of customers. Check out our interactive demos to see simplicity and value of this innovation.

Before you register, check for following basic requirements to test your readiness to take advantage of this amazing yield analysis software tool.